How CTB Can Help OEMs Delight Retail Stores & Fulfillment Centers

Attention U.S. manufacturers – do you source materials commonly used in store fixture and fulfillment center applications?

If you’re getting your laser-cut components from China, you’re probably used to delayed material arrivals, price increases, and even incorrect products showing up.

In addition, an up-and-coming concern is the mishandling of information by Chinese suppliers, including sharing your designs despite signing an NDA, lack of communication, lack of transparency, and engineering files not being shared with the buyer (QualityInspection.org).

And if you’re sourcing domestically, is your current manufacturer handling all the steps in your supply chain? Or are you having to use several vendors to complete a job?

For over two decades, Central Tube and Bar (CTB) has been helping retail manufacturers reshore by:

- Simplifying their assemblies

- Shortening their supply chain

- Offering superior customer service

- Reducing overall rejection rates

Retail Store Fixtures & the Rise of Fulfillment Centers

We hear from retail manufacturers every week struggling with delays in material arrival and inconsistent quality.

At Central Tube and Bar, we help OEMs assemble retail shelving, displays, base decks, gondolas, kiosks, apparel racks, and any kind of custom fixtures by alleviating all of these major concerns.

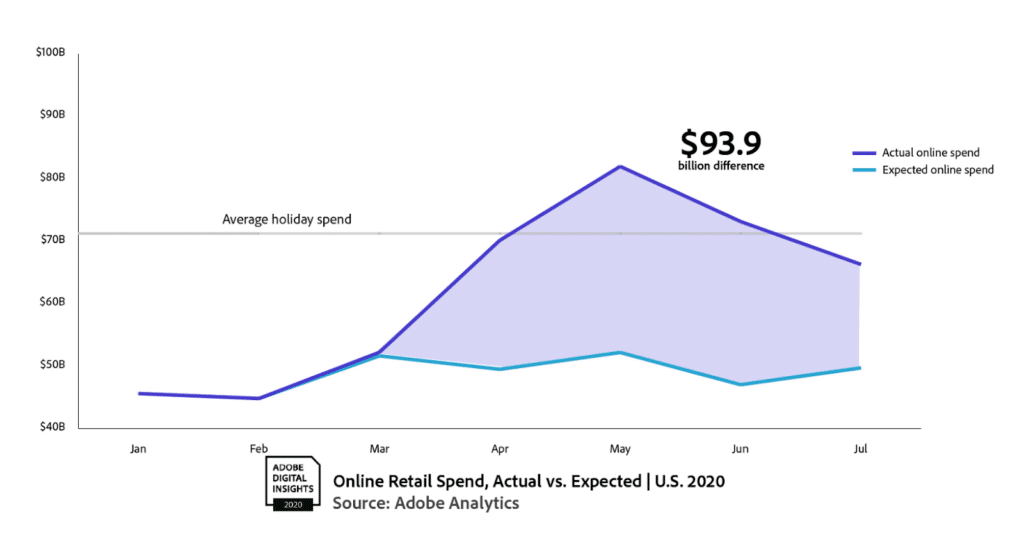

There are also many OEMs facing a big push towards fixtures for fulfillment centers as online shopping habits rise. Adobe’s May 2020 Digital Economy Index found e-commerce shopping levels during COVID-19 were higher than the 2019 holiday season.

Quickly Growing

While online shopping slowed slightly in July 2020 as more physical stores opened up, current projections show that by October 5, online spending for 2020 will surpass all of 2019’s online spending.

Source: Adobe Analytics

Major retailers are expanding and building more fulfillment centers to respond to the increased need for quick shipping and delivery. In June alone, Amazon announced its plans for new fulfillment centers in Chicago and Grand Rapids and Kroger announced its joint venture with Ocado to build three fulfillment centers across the country.

Are you poised to offer these retailers the fixtures they need to get their fulfillment centers up and running?

Reduce Rejection Rates for Your Retail & Distribution Center Customers

It’s fairly standard to have rejection rates reaching 20-25% when sourcing from Chinese suppliers. When your final product doesn’t meet quality standards, it not only hurts your bottom line – it hurts your reputation.

This is the exact problem Steve Conrad, Manufacturing Engineer of Assembled Products Corporation (APC), was facing when sourcing tubular parts for its motorized electric shopping cart used in many retail stores.

Steel tubing was used throughout the product, and for many years, APC sourced it from China. But suddenly, they started noticing bends where the tube was crushed and there were issues with sizing. They started inspecting each piece by hand, and they had to deal with the welding concerns.

Their rejection rate was 20%, not to mention lost productivity.

After switching to Central Tube and Bar, APC not only got a redesign that simplified the assembly, but their rejection rate went down to less than 1%.

Reduce Weld Spots on Retail & Fulfillment Center Parts

Part of the APC redesign was reducing weld spots. This eliminates an extra step in the process and also strengthens the integrity of the part.

Unnecessary weld spots can weaken different areas of the final product, which can lead to more issues down the road involving warranties, your reputation, and even safety.

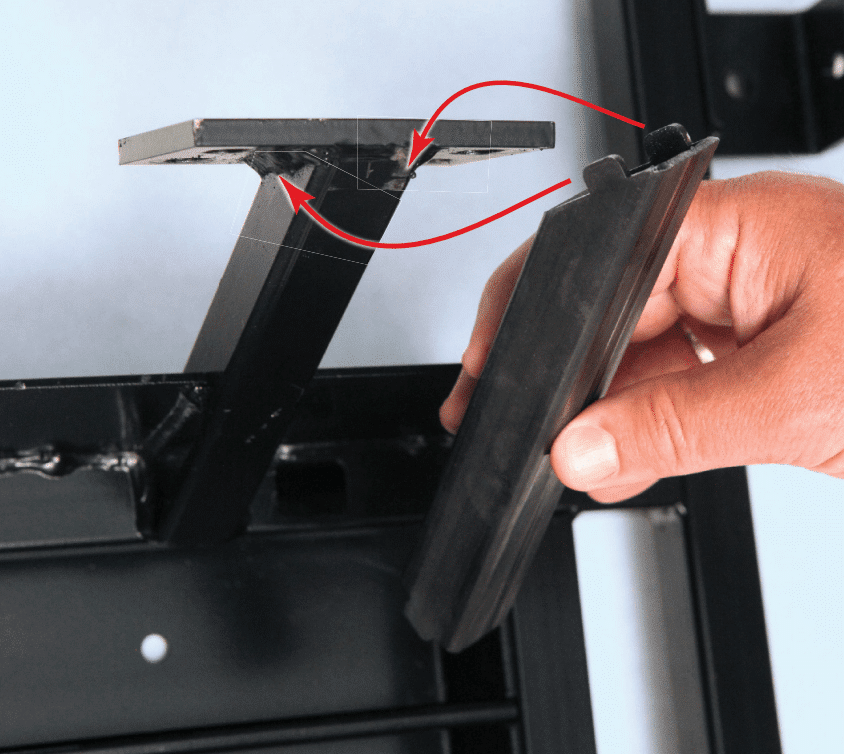

The rear bumper of APC’s cart involved an ¾” round tube that was bent into a wrap-around rail, then welded to the chassis tube. If the bumper got bent or crushed in service, a field repair was costly.

The APC repair tech would need to grind off the welds to remove a damaged bumper and weld on a new one.

redesign

After redesigning the rear bumper to remove the need for welding, the repair tech just loosens four bolts and changes out the bumpers. Not only is the end product stronger, but it’s much easier to do maintenance.

Whether you’re fabricating display units, retail shelving, distribution center racks, or apparel racks, it costs you nothing to send us your current parts. We can take a look and determine if we can redesign them to not only reduce weld spots but to make for an easier, faster assembly.

Laser tube cutting offers the flexibility to produce tabs and matching slots in frame parts that are so precise the pieces snap together for perfect welding positioning. This speeds up frame assembly.

Increase the Quality of Your Retail & Fulfillment Center Supplies

Getting low-quality parts is one thing, but getting the wrong part altogether is beyond frustrating. Lead times from overseas can exceed 15 weeks, so when you wait that long just to get inaccurate parts, it’s a quick way to destroy your entire operation.

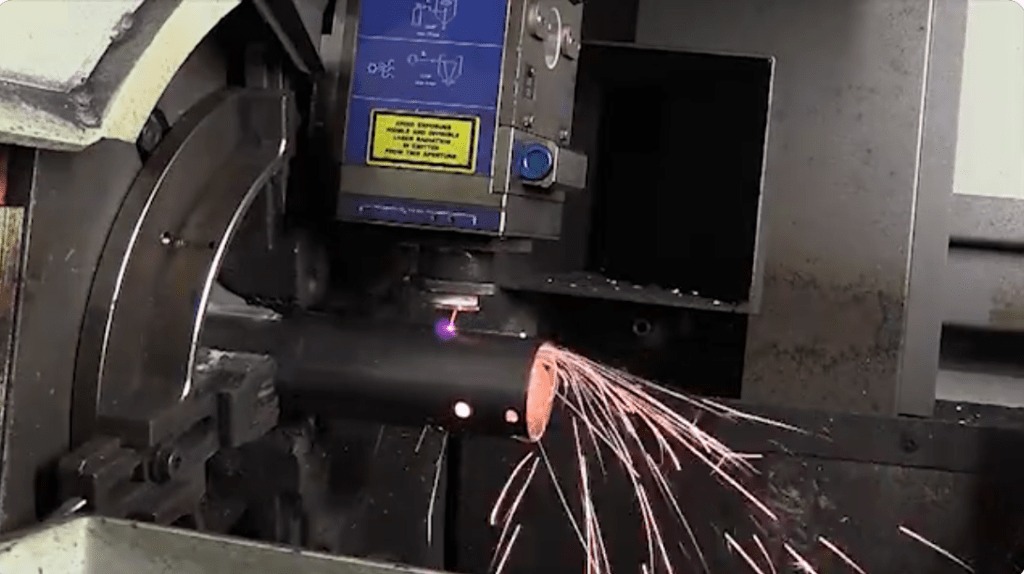

Here at Central Tube and Bar, we have the most advanced machines in the industry to deliver you precise cuts that are repeatable every time. From the BLM LT5 Fiber Tube Laser to the Mazak Fabrigear 300, our machines help us complete your projects faster and more accurately.

The BLM LT5 Fiber Tube Laser making precise circular cutouts

The Mazak 300 making precise cuts through tubing

In addition to our investment in technology, we source our materials from the North American Steel Alliance co-op and a preferred list of 50 vendors, meaning you get access to the highest quality tube and bar products. Our superior supply chain network allows us to competitively source prime materials quickly and economically.

Do some of your customers require only domestically sourced products? All of our carbon steel, stainless, and aluminum are sourced and made right here in the USA.

The combination of superior stock and our dedication to technology and automation allows you to enjoy a high-quality product that withstands more wear and tear.

Reduce Steps In Your Supply Chain

The more steps you add to your supply chain, the more chances something goes wrong. Delays, price increases, lines being shut down, currency changes, and more are common issues suppliers face when sourcing parts overseas.

And if you source your parts domestically, are you still having to work with multiple facilities? Many OEMs use several vendors to complete welding, coating, and more just to get their finished product.

Long supply chains often require a higher minimum purchase level when compared to shorter supply chains. This leads to inventory management issues and tied up cash in held stock that may move slowly.

Here’s the bottom line: if you can shorten your supply chain, you decrease the chances of something going wrong, and you actually save money in the long run.

Central Tube and Bar is capable of providing secondary operations such as welding and coating in order to offer turn-key assemblies. We’ll even send a finished product right to the job sight! If you need the parts at your location, we’ll deliver the components quickly to your shop floor in order to expedite large, high volume jobs.

When you work with CTB, you reduce steps in your supply chain, which speeds up lead time and reduces the chances of a hiccup in the process.

Get 3D Models and Prototypes In House

We work with our customers to create templates for laser cutting as well as 3D prototypes in house. Our investment in industrial 3D printing technology can help you better adjust for fit, form, and function to build a superior product in less time.

Our printer rapidly allows us to produce templates for products of various shapes and sizes. Templates allow us to create quality with higher precision and accuracy for our clients.

Thanks to 3D prototyping, you can see what a product looks like and make small adjustments before placing an order with us. We can also work together to redesign your existing product and ensure it’s exactly what you’re looking for before moving forward.

All Things Considered, The Choice Is Clear

If you’re a supplier of fixtures used in retail and fulfillment center applications, Central Tube and Bar can solve some of your most painful bottlenecks.

Don’t you want to receive products faster and cheaper? How about with fewer rejections? Do some of your customers require only domestically sourced products? We’re happy to deliver on all fronts.

Our best-in-class team offers industry-leading service on pricing and delivery for the majority of materials commonly used in store fixture and fulfillment center applications.

We pride ourselves on being on time, simplifying your process, delivering excellent quality, and all for an affordable, competitive price. Plus, your clients will love that our parts are all made right here in the U.S.A.

Improve your retail store and fulfillment center processes today

What are you waiting for? Discover how Central Tube and Bar can improve your manufacturing process with a no-obligation quote.