How to Save Time and Money On Domestic Solar Power Tube Fabrication

The renewable energy market is booming – in fact, it’s the fastest-growing energy source in the United States, increasing 100% from 2000 to 2018 (Center for Climate and Energy Solutions).

While hydropower and wind power make up the bulk of our renewables today, solar power is the fastest-growing electricity source. It’s affordable and accessible, making it an ideal solution for a wide variety of industries.

Since 2008, solar panel installations in the United States have grown 35-fold to an estimated 62.5 gigawatts, enough energy to power 12 million American homes (Office of Energy Efficiency & Renewable Energy).

Here at Central Tube and Bar, we’re proud to help the solar power industry produce high-quality posts, panel brackets, panel frames, and more right here in the United States.

We’re also excited about helping entrepreneurs bring their life-changing renewable energy visions to life.

want to learn more about how you can save money today?

Contact us today and let's look over your prints to see how we can get you the best parts on time, every time.

Solar Power Demand Increases with Government Incentives

Many U.S.-based energy projects incentivize businesses to source materials domestically. For example, one of our solar energy clients out of Austin, TX gets grants from the United States government to develop his solar energy product.

That grant money is given to pursue his idea of a solar tree, ideal for agricultural areas (more on that shortly).

And that’s just one example – the government is incentivizing homeowners and businesses to install solar panels, offering tax credits equal to 26% of the cost of the solar panel system (EnergySage).

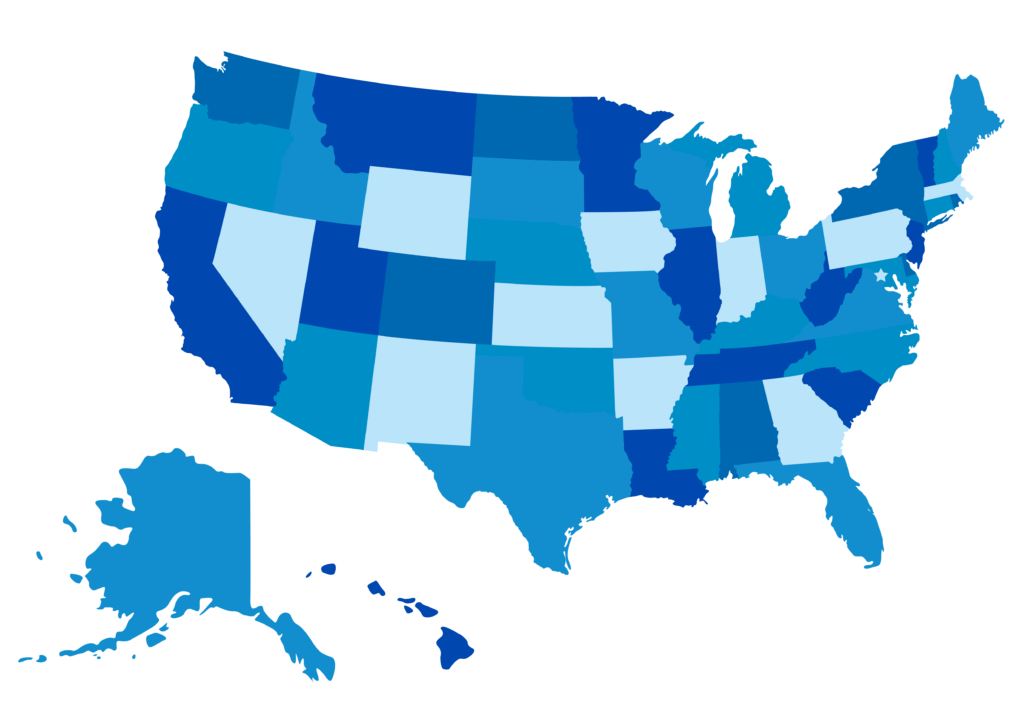

Solar energyon the rise

On top of that, many states offer additional tax credits, which allows homeowners and businesses to deduct a portion of their solar panel system from their state tax bill (Database of State Incentives for Renewables & Efficiency). Rebates between 10-20% are also available from utility companies and other organizations wanting to promote solar energy.

Needless to say, solar energy is more affordable than ever before, and demand is increasing at an unprecedented rate.

The incredible solar energy spike is forcing OEMs to look for ways to:

- Cut costs

- Shorten the supply chain

- Make improvements to their solar products

- Increase efficiency of their components

- Source the highest quality steel and aluminum

That’s where Central Tube and Bar can help.

Tube Laser Services for Solar Power Parts

Many organizations we work with need solar energy components made in the United States.

Common hurdles include:

- Lengthy lead times

- A complex supply chain

- Difficulty finding high-quality components domestically

At Central Tube and Bar, we were able to fabricate posts, panels, mounts, and frames in a short amount of time and even deliver them straight to the job site.

For almost all of our clients, we’re able to speed up their lead time and simplify their overly complex supply chain. Plus, CTB is located in the United States, and we source all of our parts domestically.

Bottom line: if you’re looking for ways to save money and time, CTB can help.

Case Studies

We’ve worked with a variety of individuals and organizations in need of solar power components. The common theme among every project is the need to source high-quality materials domestically at a competitive price. Check, check, and check!

From Germany to the United States

One organization was bringing in a lot of pre-fabricated metal from Germany.

Oftentimes, organizations believe importing metal from overseas is cheaper, but they run into quality control issues coupled with lengthy, complex supply chains.

Compared to Germany, Central Tube and Bar is domestic. We’re closer to home and can offer a shorter lead time.

Making the decision to re-shore was easy for this organization, but why CTB?

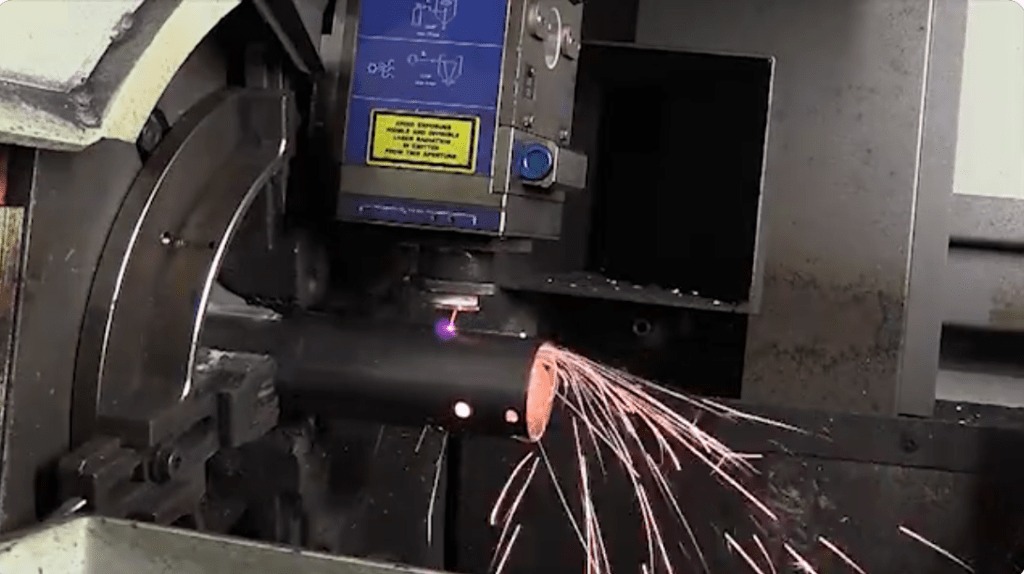

Compared to other shops in the United States, we offer more recent technology. Our machinery – namely, tube lasers – is modern and maintained. In fact, we invest millions of dollars each year towards obtaining and maintaining the latest technology in metal processing.

The BLM LT5 Fiber Tube Laser making precise circular cutouts

The result is shorter lead times, domestically sourced and processed materials, and unmatched precision.

Beyond our superior technology, our materials are all prime. Other fabrication shops in the United States may buy imports or seconds, leading to lower quality components which ultimately reflects on your reputation and can damage your bottom line in the form of rejects, warranties, and lost customers.

Our materials are:

- Prime: expect newer, cleaner, and rust-free components. CTB’s prime metals add to the longevity of your parts.

- Galvanized: your components can be galvanized, solving a big piece of the puzzle for people putting solar equipment outside.

The end user wants high-quality solar energy parts that will withstand the elements and stand the test of time. It all begins with superior components, which we’re proud to supply here at CTB.

High Volume Solar Post Orders

Another client we worked with had a massive project – they needed to fabricate a high volume of components at a competitive price, all done in the United States.

They needed solar posts that would be driven into the ground. On one end, we laser cut some holes to mount the bracket to, which pivots the solar panel with the direction of the sun.

We’re proud to be able to fabricate thousands of these components in as little as two weeks. That short lead time combined with a short, simple supply chain made the decision easy for this client. They switched to CTB and also realized several other benefits, including our dedication to service.

We oversee the installation and make sure we deliver to expectations. I don’t think you get that level of service from our competitors.

In addition, we have a flat management structure. We’re family-owned, and my office is across the hallway from the President’s office.

When our clients talk to their representative, they can get a decision quickly. It’s frustrating when the person you’re working with isn’t a decision-maker, because it drags out the process.

Because we don’t have layers of management, we’re flexible, and our clients have come to appreciate that.

Prototyping and Seeing the Solar Tree Vision

Our final case study features a visionary out of Austin, TX who created his own product called a solar tree.

The U.S. government granted him funding to pursue his idea, and he went full time.

He came to us with this concept of a solar tree that could be spread out sporadically across fields in an agricultural setting. Currently, solar panels take up a lot of space, and farmers can’t use that space to plant crops.

His solar trees would free up the land and have little to no impact on the farmer’s crop capability. Ultimately, his idea lessens the footprint of solar-powered generation in fields. We loved that idea and worked with him on a prototype.

We took the time to help explain different materials and availabilities to help him fulfill his vision.

We’re currently on our second round of prototyping and are working towards a final design that achieves this noble goal of limiting the footprint of solar power.

We love helping fulfill our clients’ visions with innovative solutions that have the power – pun intended – to change the world.

Next Steps

If you’re looking for tube laser services, Central Tube and Bar is the premier tube laser fabrication company, and we don’t say that lightly!

Our size in terms of capacity as well as our experience in the field make us the tube laser experts you can rely on. We adopted this fabrication technology in 1996 and were one of the first companies in the United States to buy a tube laser machine. We’ve bought new machinery about every other year since.

When it comes to tube fabrication, we can confidently say we’ve been doing it the longest and can offer the most competitive prices. Our solar power clients also love that we can introduce new features to their existing components that provide efficiency gains.

If you’re in need of solar posts, solar panels, solar frames, or any components for your solar power project, contact us here at CTB to get started.

Save time and money today

Let’s discuss your needs, take a look at your component prints or solid models, and put together a quote.